Problems :

Apple said it collected more than 40,000 tons of e-waste in 2014, recovering enough steel to lay 100 miles of railway track. Li Tong Group, with three recycling sites in Hong Kong and a dozen more worldwide, expects 20% growth in global capacity this year.

Other corporations that crank out new products that will eventually reach the end of their lives have jumped on the e-cycling bandwagon. Verizon reached its 2010 target of recycling 2 million pounds of electronic waste and is shooting to collect 2 million more pounds by 2020. NextWorth Solutions is buying into the movement, too

Case Study: Guiyu, China :

he city of Guiyu and surrounding towns in the Guangdong region of China has been the site of the largest E-waste recycling site in the world since the mid 1990’s. Although the exact amount of E-waste flowing onto this area is unknown due to the fact that it’s illegal and therefore no one keeps records. (Robinson 187) Guiyu has a population of 150,000, and it is estimated that 80% of families have members engaged in e-waste recycling operations. The villagers and migrant workers use environmentally unsound techniques to recycle E-waste, such as, manual removal disintegration of electronic components, open burning to reduce mass and extract precious metals, and open acid digestion to recover precious metals. These crude recycling techniques have resulted in widespread environmental contamination of the surrounding water systems, soils, and air.

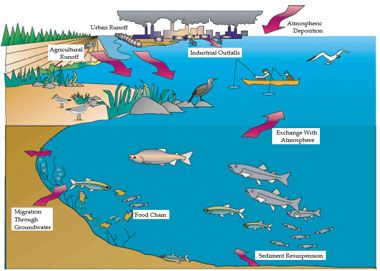

Water and Aquatic System :

E-waste contaminates enter the water system through the direct dumping of acid waste into streams and ditches, through the settling of airborne particles, or through the leaching of soils. In December 2001, the Basel Action Network (BAN), a non-governmental organization (NGO) focused on confronting the global environmental injustice and economic inefficiency of toxic trade, conducted a series of tests on the water sediment, and soils along the Lianjiang River, running through Guiyu. The water samples taken showed lead, a toxic metal at high concentrations, at levels 2,400 times greater than the World Health Organizations maximum limits standard. Sediment samples taken reveled levels of Barium 10-times higher, and chromium was 1,338-times greater than the EPA threshold for ecological risks. Cadmium was found to be 52-times greater than EPA sediment screening benchmark. Tin was discovered at levels 152 times the EPA threshold. The study further revealed elevated levels of silver (Ag), lithium (Li), Molybdenum (Mo), antimony (Sb), and Selenium (Se) in the Liangiang River (Exporting Harm, 2002).

Soils :

Soils located near Guiyu E-waste recycling areas where acid leaching and subsequent dumping, contained numerous and drastically increased amounts of chemicals. While PBDEs (a flame retardant used in computers) are not found naturally in farm soils researchers found the soil contained up to 4250ng/g of PBDEs. They also found very high levels of PCBs 330ng/g, PCDD 100ng/g, dibenzofurans Fs 330ng’g, and PAHs at 20,000 ng/g. These substances have been found to cause genetic damage to plant and animal life. Unfortunately, all of these elements have been found in plant life surrounding Guiyu. Moreover, analysis of rice samples from near Guiyu revealed concentrations of Lead and Cadmium in processed rice to be 2-4 times in excess the maximum allowable concentrations of the elements in marketable food stuffs. Due to these chemicals tendency to cause genetic mutations in plant and animal life, rice-paddy soils near E-waste recycling areas have seen a reduction in the germination of rice. (Exporting Harm, 2002)

Air :

The air in Guiyu is also highly contaminated by e-waste dust particle contamination. Air samples near Guiyu contained polychlorodibenzo-p-dioxins between 65 and 2765 pg/cubic meter, the highest level of atmospheric dioxins ever reported. Combustion of e-waste that contains flame retardants (PBDEs) has resulted in concentrations of total PBDEs of up to 16,575 pg/cubic meter in the atmosphere near Guiyu, 300 times higher than in Hong Kong. Daytime aerial contamination of PBDEs in Guiyu exceeds 11,000 pg/cubic meter during the daytime, and drops to 5000pg/cubic meter at night.

Africa :

Recycling :

After trading in a device to Apple, it’s put through several tests to determine if it can be resold on the second-hand market. Devices with too much damage or deemed unsellable are sent directly to one of the several recycling facilities throughout the world.

Apple’s recycling process consists of “the most rigid and exacting” processes when compared to other technology companies, according to the report.

Apple contracts with various recycling facilities throughout the world, one of which is Li Tong Group. Li Tong is reportedly in the process of building a new facility in San Francisco, set to open this year.

Jackson claims Apple’s effort to reverse manufacture its products result in recycling 85% (by weight) of a device. The industry goal is to collect and recycle 70% of a device.

The recycling process involves 10 steps and some 50 rules each contractor has to agree to and follow. Each operation includes a series of vacuum-sealed rooms “designed to capture 100 percent of the chemicals and gasses released during the process,” the report said.

For more details visit the link :

https://www.apple.com/in/recycling/

Green design :

They are planting 7,000 trees.

According to the project description, they are reintroducing native species.

The Apple Campus 2 landscape framework primarily compriseslandforms and vegetation found in the Oak Woodland and Oak Savanna that once were prevalent in the area…. Complex woodland planting with layered understory will provide urban habitat islands for many migrating songbirds. The vast majority of the 309 species to be planted in the new Campus are native to California. This diverse landscape will contribute significantly to the regional diversity of flora and fauna.

For more details visit the link:

https://www.treehugger.com/green-architecture/6-ways-new-apple-headquarters-will-be-green.html